Rhizome

Modular shelving system with creative attachments

🕛 January - February 2024 (10 weeks)

📍 DSGN 395: Furniture Design

👥 Mentorship from: Professor Hemant Jha, Prototyping Specialist Eric Capper

Overview

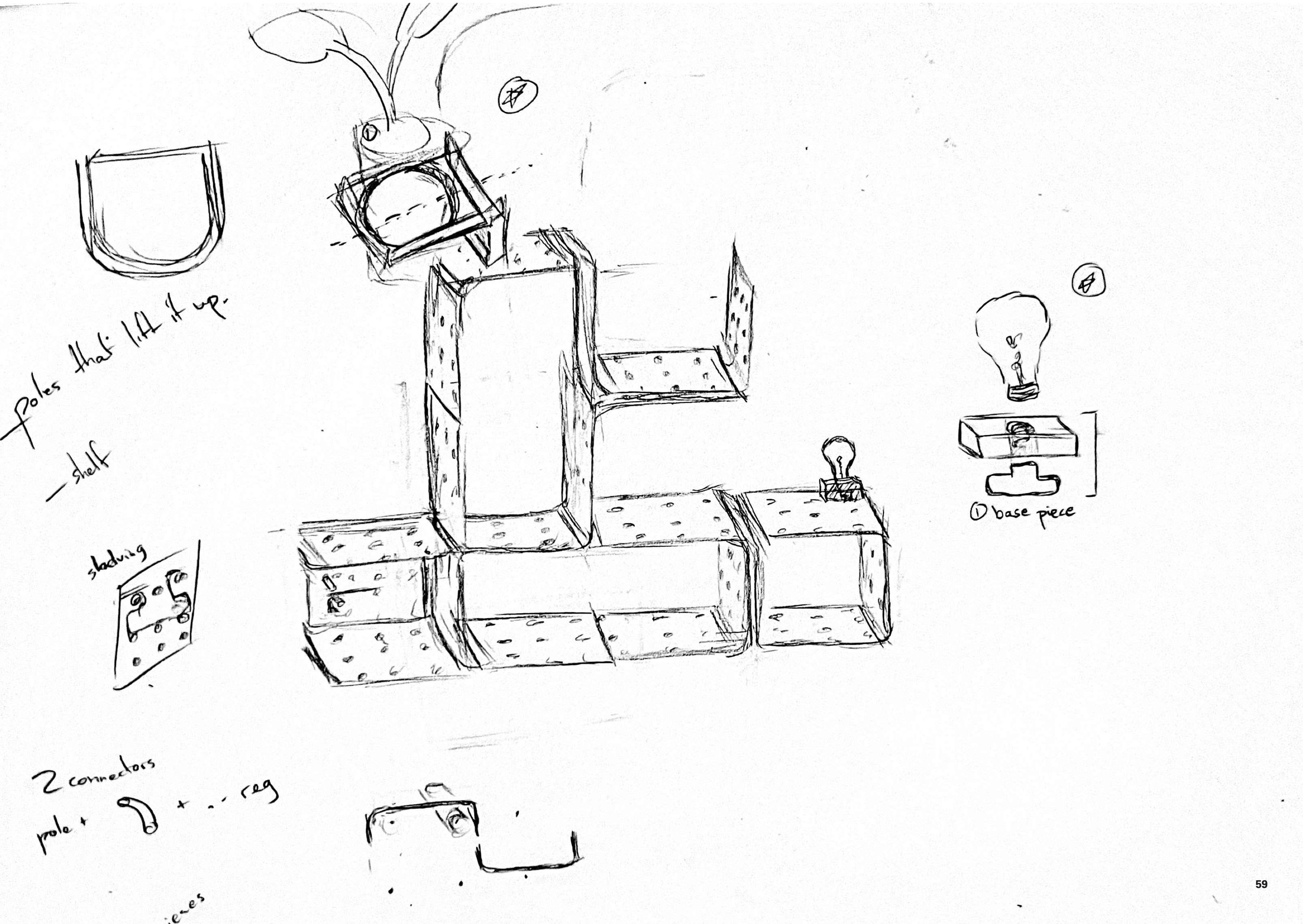

Creating this furniture piece changed me as a designer, because it was my first experience documenting my process in real time from concept to fabrication. As an avid reader and indoor plant enthusiast, I wanted to create a shelving system that simplified plant care while creating flexibility for infinite future iteration. I achieved this through hollow connectors and support beams that house various functional attachments, making the design both practical and modular.

🖱️ CAD: Rhino, 3D modeling for modular systems

⚙️ Fabrication: Metalworking, waterjet cutting, assembly

Process + book

I documented my process in Adobe InDesign to create my process book

Over 8 weeks, I designed and fabricated a modular aluminum shelf with load-bearing supports and eight interchangeable attachments for multifunctional use

Modeling

My first CAD model of Rhizome was my first CAD model, ever.

I tried to contain big ideas for parts around specific utilities by creating a physical metal frame for those ideas.

The focus was on multifunctionality. I wanted a furniture design that I could iterate on continuously.

I mocked up those functional ideas in Rhino, and printed some of them.

I modeled attachments for hanging objects on, irrigating plants (this is why all of Rhizome’s parts are hollow), lighting candles, and performing other household tasks.

I experimented with several mechanisms, landing on a printed nut and bolt that attached to any of the holes in the metal frame. All attachments would ultimately fit in the joints created in the interior of the bolts.

I needed a mini-model to prototype with on the go, given how much I had to travel during the 10-week build process.

I experimented with several mechanisms, landing on a printed nut and bolt that attached to any of the holes in the metal frame, and positioned to customize the layout of the shelf.

All attachments fit in the joints created in the hollow interior of the bolts.

The two-color design helf parts for the design showcase with one color.

I added a finish to the aluminum shelf frame with an orbital sander to match the circular cuts on the piece.

Aluminum was a much more cost-effective material, but also lighter, reflective, and adaptable, qualities that I thought plants might appreciate while still receiving sufficient structural support.

I showcased Rhizome in March and have been using my shelf prototype while working on other projects.

Reflecting on the process, my greatest success lies in Rhizome’s creative flexibility, which continues to evolve as I experiment with new materials and attachment styles. While I fell short of fully developing the water system, I’m excited to revisit and execute this concept when it’s time to reimagine my apartment layout.

When I need a quick fix (such as storing handbuilt ceramics pieces), I have fun integrating found objects into Rhizome modules.